Choosing the Right Manufacturing Processes for Water Cooling Pipe Adapters in Desktop Computers

Title: Choosing the Right Manufacturing Processes for Water Cooling Pipe Adapters in Gaming Desktop Computers

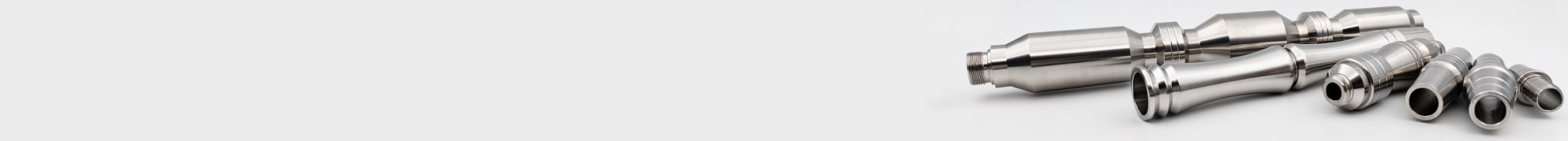

In this blog post, we will delve into the selection of manufacturing processes for Water Cooling Pipe Adapters, which are 90-degree bend connectors made of pure copper. Similar to the pipe connectors we use in our homes, these adapters are commonly used in the computer water cooling industry as a versatile component. Our production process involves precision casting, followed by CNC machining to meet the design requirements, mirror polishing for a flawless finish, and PVD surface treatment to cater to individual market preferences. Join us as we explore the intricacies of these manufacturing processes and their significance in creating Water Cooling Pipe Adapters.

Precision Casting:

To ensure high-quality Water Cooling Pipe Adapters, we employ precision casting. This process allows us to create intricate copper components with precise dimensions and a smooth surface finish. Through precision casting, we can achieve the desired 90-degree bend design, which is essential for optimal water flow and compatibility in gaming desktop computers.

CNC Machining:

After the precision casting process, the components undergo CNC machining to add essential features such as threaded connections. CNC machining ensures precise and accurate thread formation, enabling seamless integration with other water cooling components. This step guarantees a reliable and leak-free connection, vital for efficient cooling performance.

Mirror Polishing:

To enhance the aesthetic appeal and provide a visually pleasing finish, we subject the Water Cooling Pipe Adapters to mirror polishing. This process creates a smooth, reflective surface, giving the adapters a premium appearance. The mirror-polished finish also facilitates easy cleaning and maintenance, contributing to a sleek and professional look in gaming setups.

PVD Surface Treatment:

To meet market demands for personalization, we offer different colors through PVD (Physical Vapor Deposition) surface treatment. PVD coating provides a durable and vibrant finish, improving the adapters' corrosion resistance and adding a touch of individuality to computer water cooling systems. This surface treatment not only enhances the aesthetic appeal but also offers additional protection to the copper material.

Conclusion:

Water Cooling Pipe Adapters play a crucial role in ensuring effective and efficient cooling performance in gaming desktop computers. By utilizing precision casting, CNC machining, mirror polishing, and PVD surface treatment, we can achieve high-quality adapters that meet both functional and aesthetic requirements. Precision casting allows for intricate designs, while CNC machining ensures precise thread formation for secure connections. Mirror polishing provides a premium appearance, and PVD surface treatment offers customization options while enhancing durability.

We hope this blog post has provided valuable insights into the manufacturing processes involved in creating Water Cooling Pipe Adapters for gaming desktop computers. By employing these processes, we can deliver reliable and visually appealing components that contribute to superior cooling performance and enhance the overall aesthetics of gaming setups.