Manufacturing the Twisty Rod with Smoking Tip for Dry Herb Twisty Glass Blunt Vaporizer

Title: The Art of Craftsmanship: Manufacturing the Twisty Rod with Smoking Tip for Dry Herb Twisty Glass Blunt Vaporizer

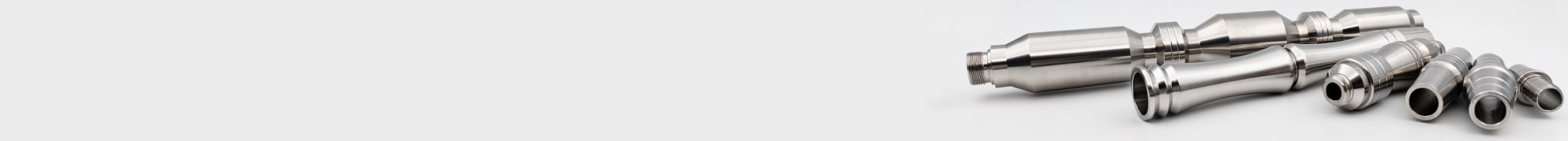

In this blog post, we will delve into the manufacturing process behind the Twisty Rod with Smoking Tip, a vital accessory for the Dry Herb Twisty Glass Blunt Vaporizer. This component is mass-produced using zinc alloy molds, and it undergoes polishing and vacuum electroplating to achieve a luxurious and sparkling appearance. Through efficient mass production, this exquisite accessory is made available at an incredibly affordable price. Join us as we explore the craftsmanship and manufacturing techniques involved in creating this remarkable product.

Zinc Alloy Molds for Mass Production:

To achieve cost-effective production of the Twisty Rod with Smoking Tip, zinc alloy molds are employed. These molds offer excellent durability and can withstand the high-volume production demands. Zinc alloy casting enables the creation of intricate details and complex shapes, ensuring the precision and quality required for the final product. By utilizing these molds, manufacturers can efficiently reproduce the Twisty Rod with Smoking Tip at a large scale, meeting market demand while maintaining affordability.

Polishing for a Flawless Finish:

Once the Twisty Rod with Smoking Tip is cast, it undergoes a meticulous polishing process. Polishing helps remove any imperfections or rough edges, resulting in a smooth and flawless surface. This step is crucial for enhancing the overall appearance and feel of the accessory. By achieving a high level of polish, manufacturers ensure that each Twisty Rod with Smoking Tip exhibits a premium aesthetic quality, adding a touch of elegance to the Dry Herb Twisty Glass Blunt Vaporizer.

Vacuum Electroplating for a Luxurious Look:

To impart a luxurious and visually appealing finish to the Twisty Rod with Smoking Tip, manufacturers employ vacuum electroplating. This technique involves depositing a thin layer of metal onto the surface of the accessory, creating a lustrous and durable coating. By carefully controlling the electroplating process, manufacturers can achieve a range of stunning finishes, such as gold, silver, or other metallic shades. This step adds a touch of opulence to the Twisty Rod with Smoking Tip, elevating its overall aesthetic appeal.

Affordability through Mass Production:

One of the remarkable aspects of the manufacturing process for the Twisty Rod with Smoking Tip is the ability to produce this luxurious accessory at an affordable price point. Through efficient mass production using zinc alloy molds, manufacturers can achieve economies of scale, reducing per-unit production costs. This cost-effectiveness, combined with the exceptional craftsmanship and attention to detail, allows consumers to enjoy a high-quality product without breaking the bank.

Conclusion:

The manufacturing process behind the Twisty Rod with Smoking Tip showcases the art of craftsmanship and efficient production techniques. By utilizing zinc alloy molds, polishing for a flawless finish, and vacuum electroplating for a luxurious look, manufacturers are able to deliver an exquisite accessory for the Dry Herb Twisty Glass Blunt Vaporizer. The combination of precision, aesthetics, and affordability makes the Twisty Rod with Smoking Tip a sought-after component in the smoking industry. We hope this blog post has shed light on the fascinating world of manufacturing and craftsmanship behind this remarkable product.