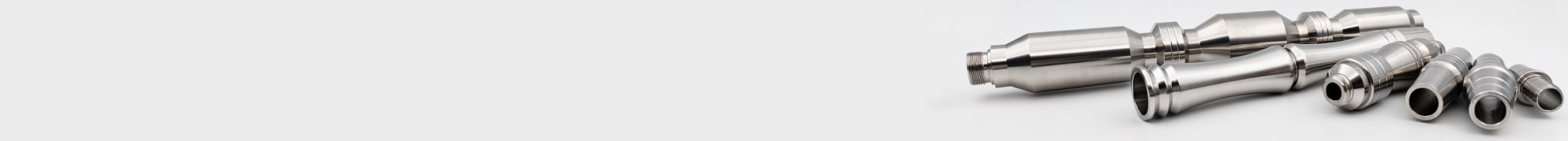

Craftsmanship Selection for Manufacturing a Coffee Machine Portafilter Funnel

Title: Craftsmanship Selection for Manufacturing a Coffee Machine Portafilter Funnel

In this blog post, we will explore the craftsmanship selection for manufacturing a coffee machine handle powder ring, made from aluminum alloy. The chosen production process involves die casting, followed by CNC machining of essential localized features. Subsequently, the part undergoes standard polishing and sandblasting techniques to enhance the surface quality. Finally, anodization is performed. However, achieving desired colors through anodization on die-cast aluminum presents challenges, as die-cast aluminum typically limits color options to silver or black. Alternative approaches and material improvements are necessary to achieve other colors due to the high rejection rate associated with the coloring process. Let's delve into the details of these production techniques and their implications.

Die Casting:

The coffee machine handle powder ring is manufactured using the die casting process. Die casting involves injecting molten aluminum alloy into a steel mold, allowing it to solidify into the desired shape. This method provides excellent dimensional accuracy and surface finish, making it suitable for complex geometries. However, die-cast aluminum poses challenges in achieving consistent and vibrant colors during the anodization process.

CNC Machining:

After the die casting process, CNC machining is employed to refine specific localized features of the coffee machine handle powder ring. CNC machines accurately remove excess material, ensuring precise dimensions and smooth surfaces in critical areas.

Surface Treatment:

To further enhance the surface quality, standard polishing and sandblasting techniques are applied. Polishing creates a smooth and reflective surface, while sandblasting creates a textured appearance. These processes improve the aesthetics and tactile feel of the coffee machine handle powder ring.

Anodization and Color Limitations:

Anodization is performed to provide a protective and decorative coating to the aluminum alloy surface. However, achieving desired colors on die-cast aluminum is challenging due to the limitations of the process. Typically, die-cast aluminum is limited to silver or black finishes. To achieve other colors, extensive improvements in die-casting techniques and material selection are required. It's important to note that the rejection rate for achieving desired colors through anodization on die-cast aluminum is relatively high.

Conclusion:

The craftsmanship selection for manufacturing the coffee machine handle powder ring involves die casting, CNC machining, surface treatment, and anodization. Die casting offers excellent dimensional accuracy and surface finish, while CNC machining ensures precise localized features. Surface treatment techniques like polishing and sandblasting further enhance the appearance and texture. However, achieving desired colors on die-cast aluminum through anodization presents challenges and requires further process improvements. Understanding the limitations and possibilities of these production techniques is crucial for selecting the most suitable approach for manufacturing high-quality coffee machine handle powder rings.

We hope this blog post has provided valuable insights into the craftsmanship selection process for manufacturing the coffee machine handle powder ring, along with an exploration of die casting, CNC machining, and surface treatment techniques.