Exploring Upi's QC Department

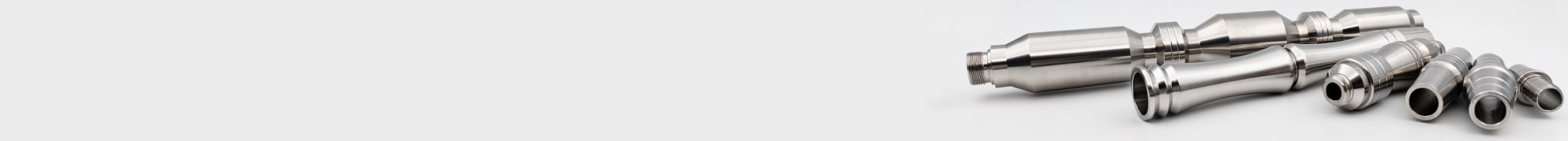

At Upi Metal Products Co., Ltd., our Quality Control (QC) Department stands as a cornerstone in ensuring the precision and reliability of our manufactured components. The QC team is equipped with a diverse range of state-of-the-art testing equipment, addressing dimensions accuracy, positional precision, shape precision, hardness, surface treatment, color, and various other critical parameters.

## QC Equipment Overview:

### 1. **Quality Assurance:**

- **Functionality:** A comprehensive suite of testing equipment to ensure the highest standards of quality across multiple parameters.

- **Key Devices:**

- **Vickers Hardness Tester:** Evaluates material hardness using the Vickers scale, providing insights into material strength.

- **Rockwell Hardness Tester:** Measures material hardness through Rockwell scales, offering versatility in hardness testing.

- **Coordinate Measuring Machine (CMM):** Ensures dimensional accuracy through precise measurement of geometric characteristics.

- **Vision Measuring Machine:** Utilizes optical measurement for assessing complex part geometries and features.

- **Surface Roughness Tester:** Quantifies surface textures and irregularities, crucial for functional and aesthetic components.

- **Run-Out Instrument:** Measures the degree of axial and radial run-out in rotating parts, ensuring smooth operation.

- **Color Difference Meter:** Evaluates color consistency and variation, vital for components with specific aesthetic requirements.

## Quality Control Applications:

### 1. **Dimensional Accuracy:**

- The CMM guarantees precise measurements, ensuring components meet design specifications.

### 2. **Hardness Testing:**

- Vickers and Rockwell testers assess material hardness, ensuring components withstand intended loads.

### 3. **Surface Quality:**

- Surface Roughness Tester maintains the desired surface finish, critical for both functional and visual aspects.

### 4. **Color Consistency:**

- The Color Difference Meter ensures components meet exact color requirements, crucial for various industries.

Our QC Department is committed to upholding the highest quality standards. Through meticulous testing with advanced equipment, we guarantee that Upi's components not only meet but exceed industry benchmarks. At Upi, precision and quality are paramount in every step of our manufacturing process.