Exploring Upi's MIM Department

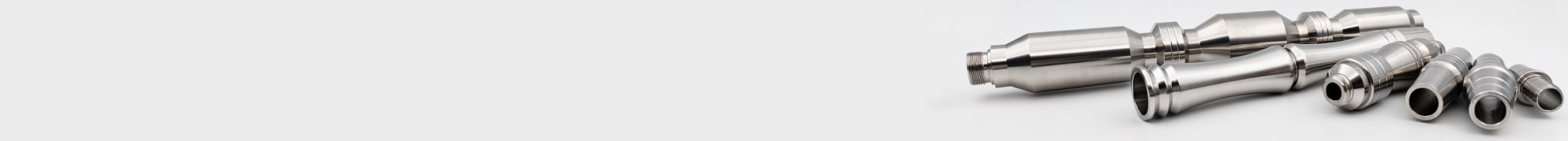

In the realm of advanced manufacturing, Upi Metal Products Co., Ltd. houses a sophisticated Metal Injection Molding (MIM) Department. This department is equipped with a variety of injection molding machines of different tonnages, along with debinding, sintering, and post-processing equipment.

## Metal Injection Molding (MIM) Process Unveiled:

### 1. **Injection Molding Equipment:**

- **Applications:** Widely employed in the production of components for industries such as smartphones, watches, electronics, appliances, printers, medical devices, machinery, automotive, marine, and jewelry.

- **Versatility:** Capable of producing complex components by injecting a feedstock composed of metal powders and binders into precision molds.

### 2. **Debinding Process:**

- **Functionality:** After molding, the component undergoes a debinding process to remove the binders, leaving the part with the metal powders loosely bound.

- **Significance:** This intermediate step prepares the part for the subsequent sintering process.

### 3. **Sintering Process:**

- **Procedure:** The part is subjected to high temperatures in a controlled atmosphere, causing the metal powders to fuse, resulting in a fully dense and functional metal component.

- **Advantages:** Sintering enhances the mechanical properties and ensures the part achieves its final form.

### 4. **Post-Processing:**

- **Processes:** Various post-processing steps, such as machining, heat treatment, and surface finishing, are employed to meet specific requirements.

- **Enhancements:** Post-processing ensures the final components meet stringent quality and performance standards.

## MIM in Diverse Industries:

### 1. **Electronics and Appliances:**

- MIM components play a vital role in the electronics and appliance industries due to their intricate designs and high precision.

### 2. **Medical Devices:**

- Precision and complex geometries make MIM components ideal for medical instruments, where quality and reliability are paramount.

### 3. **Automotive and Marine:**

- MIM contributes to the automotive and marine sectors by providing lightweight, high-strength components with intricate details.

### 4. **Jewelry Industry:**

- In the jewelry industry, MIM allows for the cost-effective production of intricate and detailed metal components.

Upi's Metal Injection Molding Department stands as a testament to our commitment to precision engineering across a multitude of industries. With our range of injection molding and post-processing equipment, we are well-positioned to meet the unique demands of our clients, ensuring the highest standards of quality and performance. At Upi, we mold excellence through Metal Injection Molding precision!