Craftsmanship Selection for Manufacturing a Coffee Machine Portafilter

Title: Craftsmanship Selection for Manufacturing a Coffee Machine Portafilter

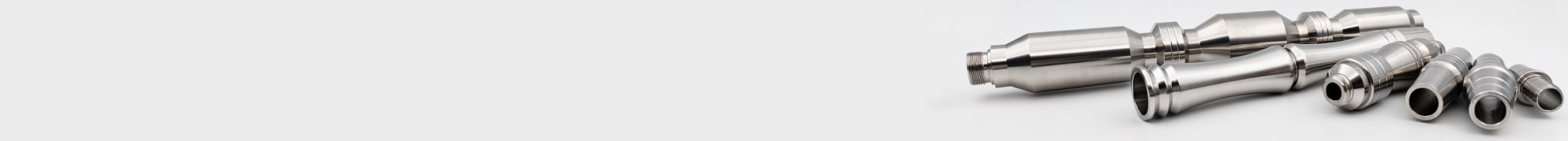

In this blog post, we will explore the craftsmanship selection for manufacturing a coffee machine portafilter's metal body, which is made from 304 stainless steel. The production process involves precision casting, followed by CNC machining of specific critical areas. Finally, the metal body undergoes a mirror polishing process to achieve a high-quality finish. We will delve into the details of these production techniques and their significance in creating a superior coffee machine accessory. Let's dive in!

Precision Casting:

The first step in manufacturing the coffee machine portafilter is precision casting. Precision casting, also known as investment casting, is a process that utilizes a wax pattern and ceramic shell mold to create the desired metal shape. The wax pattern is created by injecting molten wax into a mold, which is then coated with ceramic layers to form the shell mold. Once the ceramic shell is set, the wax is melted out, leaving behind a cavity. Molten stainless steel is then poured into the cavity, filling it and taking the shape of the portafilter body. Precision casting ensures excellent dimensional accuracy and surface finish.

CNC Machining:

After the precision casting process, CNC machining is employed to refine specific critical areas of the coffee machine portafilter. CNC machining utilizes computer-controlled tools to remove excess material and achieve precise shapes and dimensions. This step ensures that the portafilter meets the required functional and aesthetic specifications. CNC machining is especially useful for creating threaded holes, precise grooves, and other intricate features that cannot be achieved through casting alone.

Mirror Polishing:

To enhance the coffee machine portafilter's appearance and create a smooth, reflective surface, a mirror polishing process is applied. Mirror polishing involves multiple stages of abrasive polishing, gradually refining the surface to remove imperfections and achieve a high-gloss finish. This process enhances the aesthetic appeal of the portafilter, making it visually appealing and easy to clean.

Craftsmanship Selection Considerations:

When selecting the appropriate craftsmanship for manufacturing a coffee machine portafilter, several factors should be considered:

1. Material Properties:

304 stainless steel is chosen for its corrosion resistance, durability, and suitability for food-grade applications. Precision casting ensures the accurate reproduction of complex shapes while maintaining the material's properties.

2. Dimensional Accuracy and Complexity:

Precision casting offers excellent dimensional accuracy and the ability to create intricate details, such as the portafilter's unique design and ergonomic features.

3. Finishing Quality:

Mirror polishing provides a premium, mirror-like finish, enhancing the portafilter's appearance and ensuring it meets the desired aesthetic standards.

Conclusion:

Craftsmanship selection plays a crucial role in manufacturing a coffee machine portafilter. The combination of precision casting, CNC machining, and mirror polishing techniques allows for the production of a high-quality stainless steel body. Precision casting ensures accurate reproduction of complex shapes, CNC machining refines critical areas, and mirror polishing enhances the portafilter's aesthetic appeal. The result is a durable, visually appealing accessory that enhances the coffee brewing experience.

We hope this blog post has provided valuable insights into the craftsmanship selection process for manufacturing a coffee machine portafilter, highlighting the significance of precision casting, CNC machining, and mirror polishing techniques.