Home Facilities Run-Out Instrumen

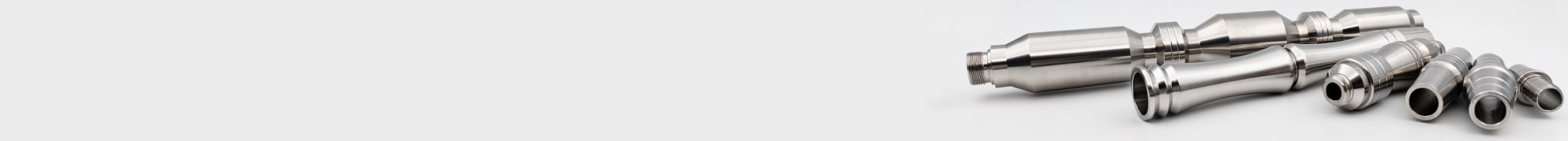

The Run-Out Instrument is an essential tool used in our factory for measuring the concentricity of metal components, particularly those with rotational characteristics. This state-of-the-art device plays a crucial role in ensuring optimal alignment and rotational accuracy, guaranteeing the highest quality of our metal parts.

The Run-Out Instrument employs advanced measurement techniques to assess the concentricity of metal components. It precisely measures any deviation from the ideal axis, allowing us to identify and rectify potential misalignments or irregularities. By analyzing the concentricity, we can ensure that our metal parts meet the stringent quality standards required for their intended applications.

Our skilled technicians and engineers utilize the Run-Out Instrument throughout the production process. From initial design stages to final inspections, this instrument aids in maintaining the precision and performance of our metal components. By employing this cutting-edge technology, we can achieve superior concentricity, resulting in enhanced functionality and reliability of the final products.

At our factory, we prioritize quality control and strive for excellence in every aspect of our manufacturing process. The Run-Out Instrument plays a crucial role in our commitment to delivering metal components of the highest precision and performance. By utilizing this advanced measurement device, we can ensure that our products meet or exceed customer expectations, leading to customer satisfaction and long-term partnerships.

Choose our factory for your metal component needs, and experience the benefits of our meticulous precision manufacturing and rigorous quality control processes.

Name: Zach Wong

Mobile:+8615889258060

Whatsapp:+8615889258060

Email:[email protected]

Add:No.29 Anhua Road, Chenghua Street, Chenghai District, Shantou City, Guangdong Province, China