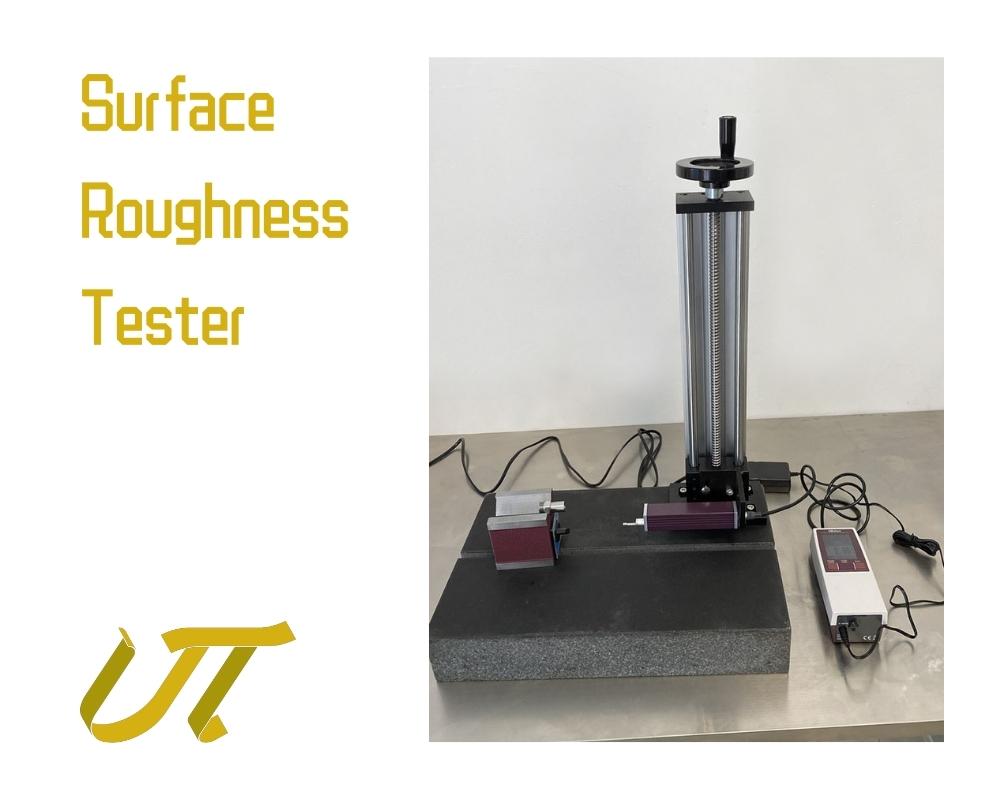

Home Facilities Surface Roughness Tester

The Surface Roughness Tester is a crucial tool in our factory's quality control process for metal components. Designed to measure and analyze the surface roughness of metal parts, this advanced testing equipment plays a significant role in ensuring the precision and excellence of our products.

Using cutting-edge technology, the Surface Roughness Tester provides accurate and detailed information about the surface texture and finish of our metal components. It enables us to evaluate parameters such as Ra (arithmetical mean roughness), Rz (maximum height of roughness), and other surface roughness indicators as per industry standards.

The device works by utilizing a stylus or a non-contact method to scan the surface of the metal component. It measures the height variations on the surface and generates a comprehensive analysis of the roughness profile. This data aids in assessing the component's functionality, durability, and aesthetic appeal.

By incorporating the Surface Roughness Tester into our quality control process, we can identify any deviations from desired surface specifications, promptly address them, and ensure consistent high-quality products for our customers. This device helps us maintain stringent quality standards, optimize production processes, and deliver metal components that meet or exceed customer expectations.

At Upi Metal Products, we are dedicated to utilizing advanced tools and technologies to deliver superior metal components. The Surface Roughness Tester is just one example of our commitment to precision manufacturing and quality assurance.

Name: Zach Wong

Mobile:+8615889258060

Whatsapp:+8615889258060

Email:[email protected]

Add:No.29 Anhua Road, Chenghua Street, Chenghai District, Shantou City, Guangdong Province, China