Home Facilities MIM Processing

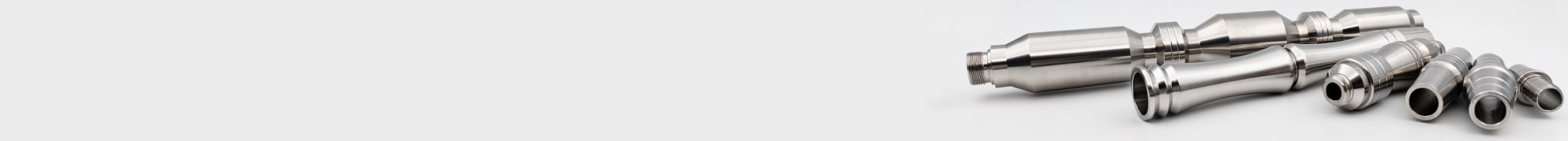

Metal Injection Molding (MIM) combines the benefits of plastic injection molding and traditional powder metallurgy techniques to produce complex metal parts with high precision and excellent mechanical properties. Our MIM factory boasts cutting-edge production equipment and utilizes the following key processes:

1. Feedstock Preparation: The process begins with the blending of fine metal powders with a thermoplastic binder to form a feedstock. The feedstock is carefully formulated to achieve the desired properties and flow characteristics.

2. Injection Molding: The feedstock is injected into a mold cavity under high pressure, precisely replicating the intricate details of the part. This stage ensures consistent and repeatable production of complex shapes.

3. Debinding: The molded parts undergo a thermal debinding process to remove the majority of the binder material, leaving behind a porous green part.

4. Sintering: The debound parts are subjected to controlled high-temperature sintering, during which the metal particles fuse together, densifying the part and eliminating porosity. This results in the final metal component with enhanced mechanical properties.

5. Secondary Operations: Depending on the application requirements, additional post-processing operations such as machining, heat treatment, and surface finishing may be employed to achieve the desired characteristics and aesthetics.

Metal Injection Molding (MIM) has revolutionized the manufacturing of intricate metal components, offering design freedom, cost-effectiveness, and excellent material performance. Upi Metal Products excels in delivering top-quality MIM parts for diverse industries, ensuring customer satisfaction and innovation in every project. Contact us today to discuss your specific requirements and experience the advantages of MIM technology.

Name: Zach Wong

Mobile:+8615889258060

Whatsapp:+8615889258060

Email:[email protected]

Add:No.29 Anhua Road, Chenghua Street, Chenghai District, Shantou City, Guangdong Province, China